Lightweight Structures Software - EASY

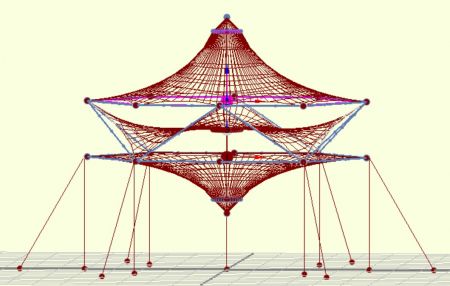

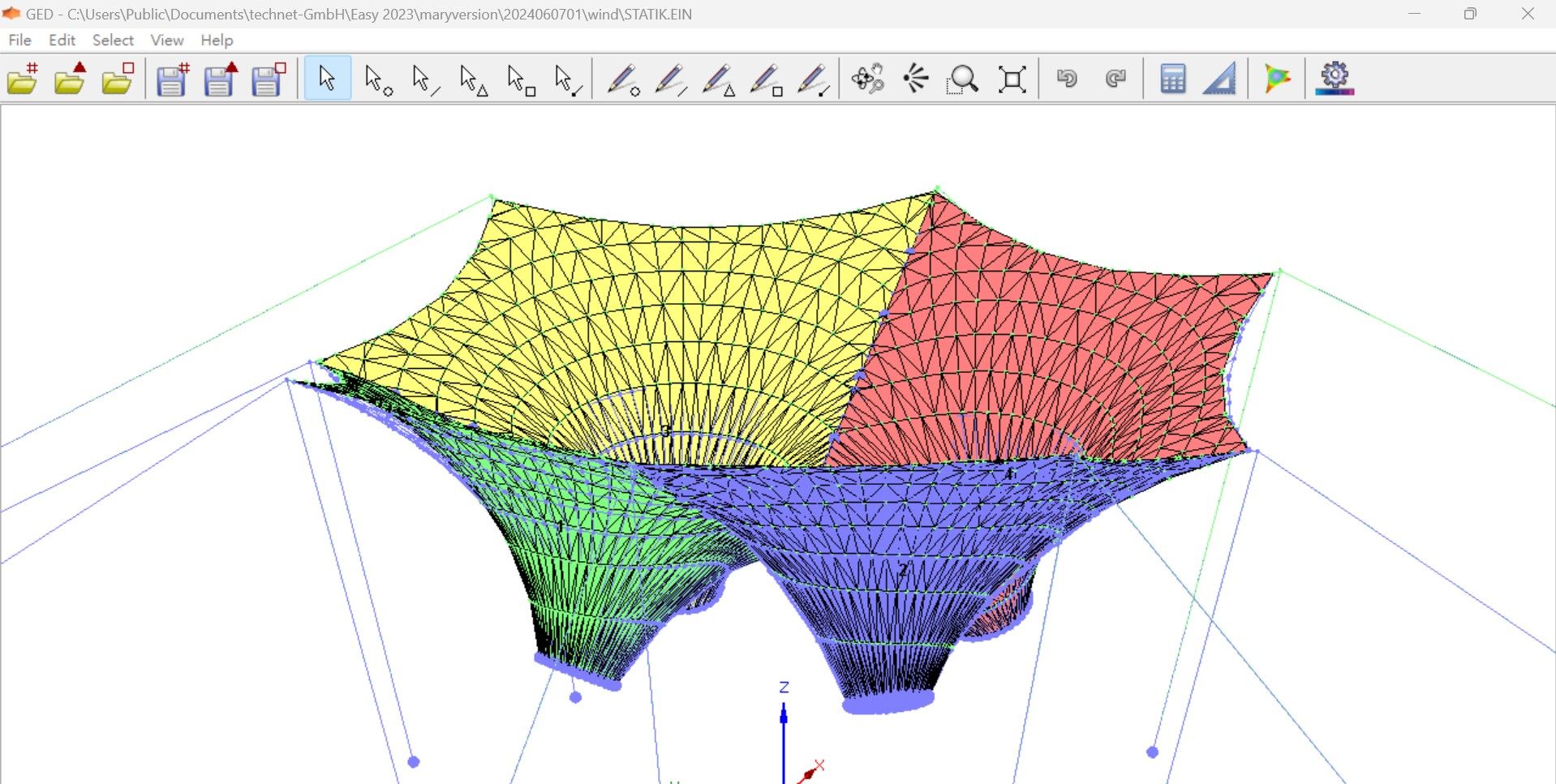

Wen's Phoenix Corp. adheres to the spirit of innovative research and development and exclusively introduces German membrane structure software "Easy". This software can quickly convert customers' CAD drawings into graphics with correct proportions, and can be used to create membrane structure designs of various shapes. Using this software, customers can integrate simulation images into their construction scenarios and analyze in advance whether the membrane structure design can withstand wind, rain or external gravity, and predict water accumulation and water leakage.

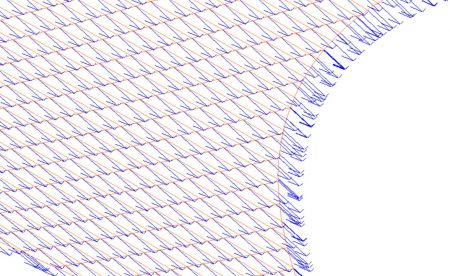

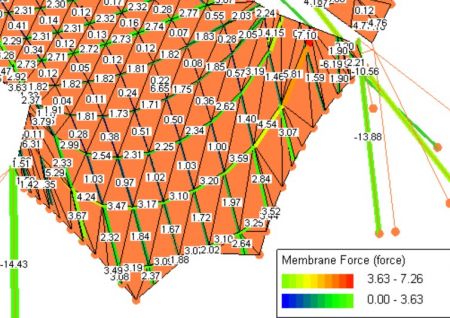

Easy software can also accurately calculate the membrane force, membrane stress and membrane deformation data after pulling between the membrane structure and the force-applying suspension point. Designers can know in advance whether the size and erection height of these membrane structures are feasible, and determine whether the pillar steel structure materials used are suitable, which can effectively reduce costs.

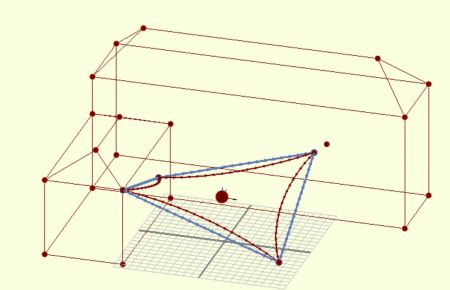

Customers' CAD drawings can be directly imported into the production, or the design can be drawn manually by yourself

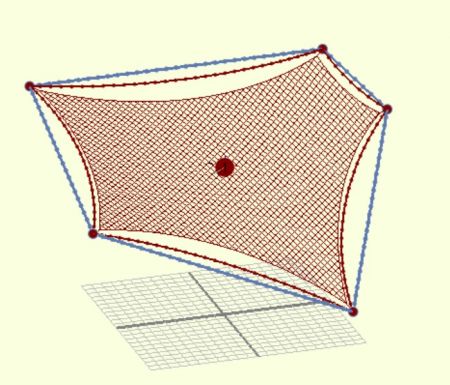

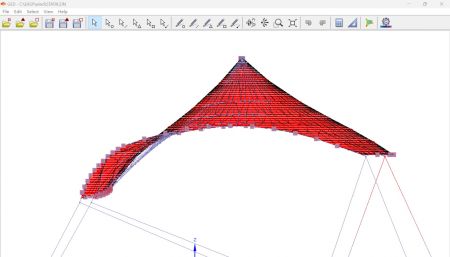

(2) After using Easy software to create membrane structure designs of various shapes, analyze wind load, snow load, water accumulation and water drainage. The membrane structural strength, membrane stress and membrane deformation data can also be calculated to determine the feasibility of the design.

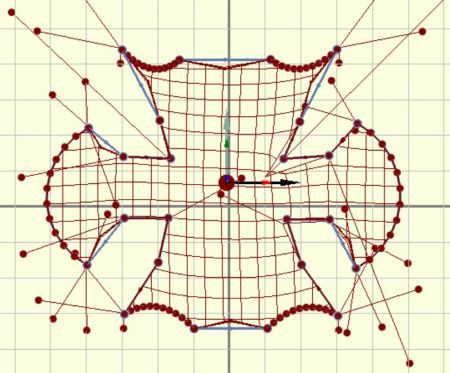

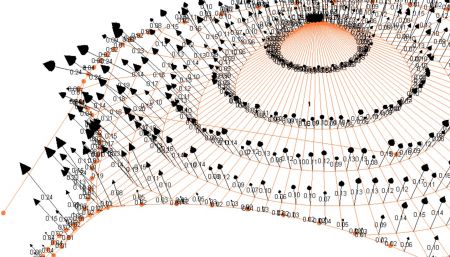

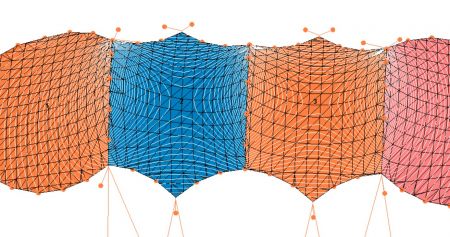

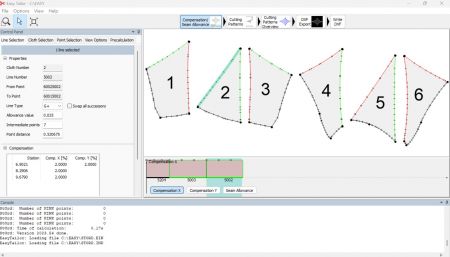

(3) Use software to quickly calculate the curvature of the membrane structure and convert the designed 3D membrane structure into 2D plane cutting

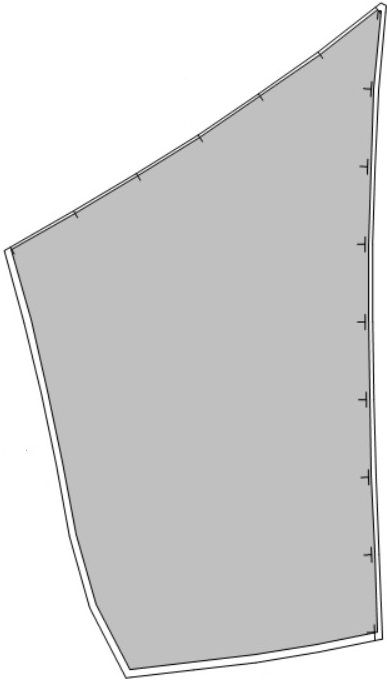

First design the conical membrane structure and then cut it with Easy software. The software will automatically bring out a cuttable 2D drawing based on the fabric width parameters and mark the welding position.